In a market driven by production efficiency, sustainability and nutritional security, choosing the right source of vitamin D has become a strategic advantage. Among the available options, Bio D®, from Huvepharma®, stands out not only for its effectiveness, but also for its production process: rigorously controlled fermentation ensures high levels of purity, consistency, and superior performance. In addition, it allows the delivery of the same amount of vitamin with lower inclusion levels per ton, optimising the formulation.

Fermentation production: what does it really mean and why does it matter?

- Stability and safety

The final molecule also offers better resistance to feed processing, as well as to the challenges of transportation and storage time.

- Industrial standardisation

Each batch is standardised in size, colour, and purity, a process carried out with high quality control, ensuring a highly safe product, thus being an excellent ally for precision nutrition.

- Sustainability

Compared to complex synthetic processes, fermentation reduces waste and energy consumption.

Bio D® is a metabolite capable of accurately reflecting the actual vitamin D status in the body.

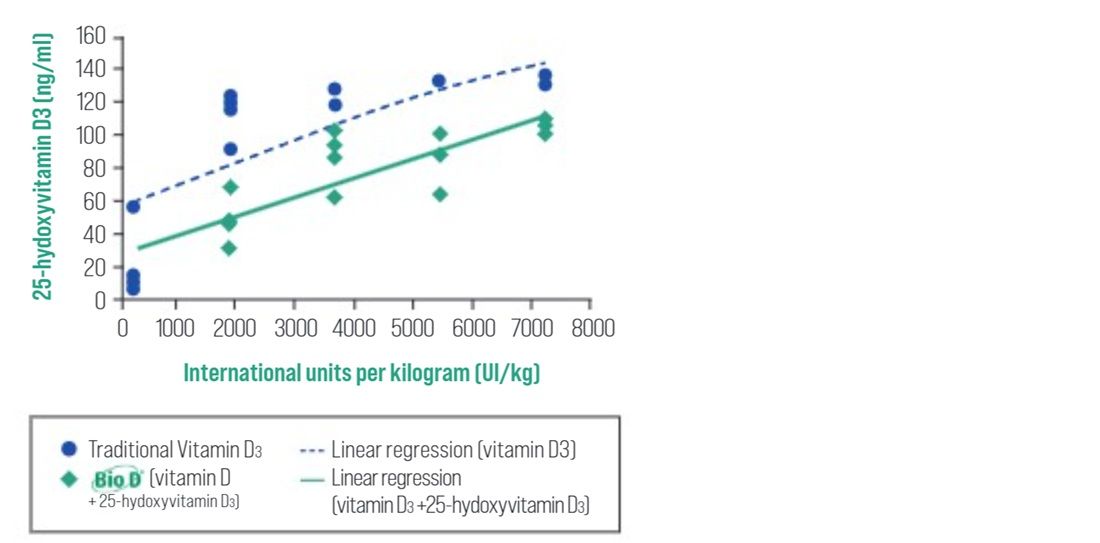

Data presented in international studies show that Bio D® promotes superior absorption (83% vs 66%) and greater retention (93% vs 80%) compared to traditional vitamin D.

Supplementation with Bio D® allows:

- faster response compared to conventional vitamin D

- elimination of the initial hepatic conversion step

- better retention and higher bioavailability

- greater metabolic predictability

Bio D® delivers superior performance with lower inclusion, surpassing other vitamin D sources and generating greater profitability for the producer. A modern solution, aligned with the current requirements of the animal production market.

Bio D® reaffirms Huvepharma®'s commitment to technology, precision and has established itself as an advanced option in vitamin D supplementation.